Drawing pipes

...

The thermal losses can also be added to the pipes. If you click on the pencil on the right in the main parameter list, the pop-up shown below will appear. The classes that can be selected are based on the German standard DIN EN 12828.

The isolation value changes depending on the pipe diameter, this is shown in the table below for class 1 to class 6. The thermal losses will be calculated during a dynamic simulation in function of the pipe length, pipe diameter, isolation class en the environment temperature.

...

Isolation thickness = 0,06 m

Thermal capacitance

To include a correct “delay” for heating up and cooling down the pipes, thermal capacitance can be activated on the pipes. The user can activate the capacitance by inserting the desired thermal capacitance in the parameter input window.

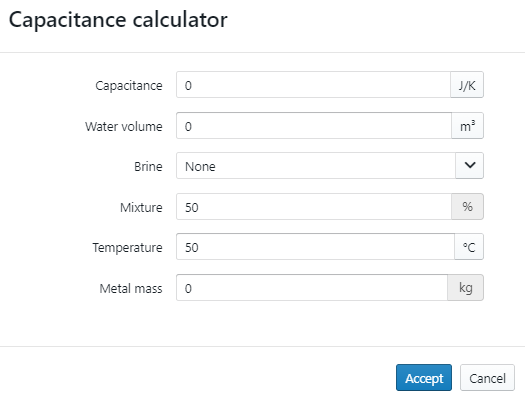

The user can also calculate the capacitance by clicking on the pencil icon next to the input window shown below. After clicking on it a popup window will appear in which specifications can be entered to calculate the capacitance.

The equation for capacity calculation is the following:

C [J/K] = m [kg] . c [J/kg.K]

With “m” as mass and “c” as the specific heat of water, brine and/or steel. The specific heat is already available in the software so it doesn’t have to be implemented. The specific heat for water and brine in our software depends on the temperature inserted in the calculator.

Using capacitance in pipes is recommended when simulating a model with a significant pipe network such as district heating networks because it increases the accuracy.

However, when using capacitance for a project, it is recommended not to use extremely large pipe segments (e.g. 1 km long) and therefore extremely large thermal capacitance. That 1 capacitance for the large pipe segment might be equivalent to a thermal store of 10 m³ which is significant. While in reality, the actual capacitance in that 1 pipe is similar to an infinite amount of small thermal stores throughout that pipe segment. Therefore it is recommended for large pipe segments to split them up and divide the capacitance over these segments to increase the accuracy.

Zeta- value

In addition to the linear pressure drops in the straight pipe pieces, additional pressure drops occur in the tubing network as a result of the resistance to the flow of water during changes in flow direction and / or water velocity. This occurs mainly at:

...